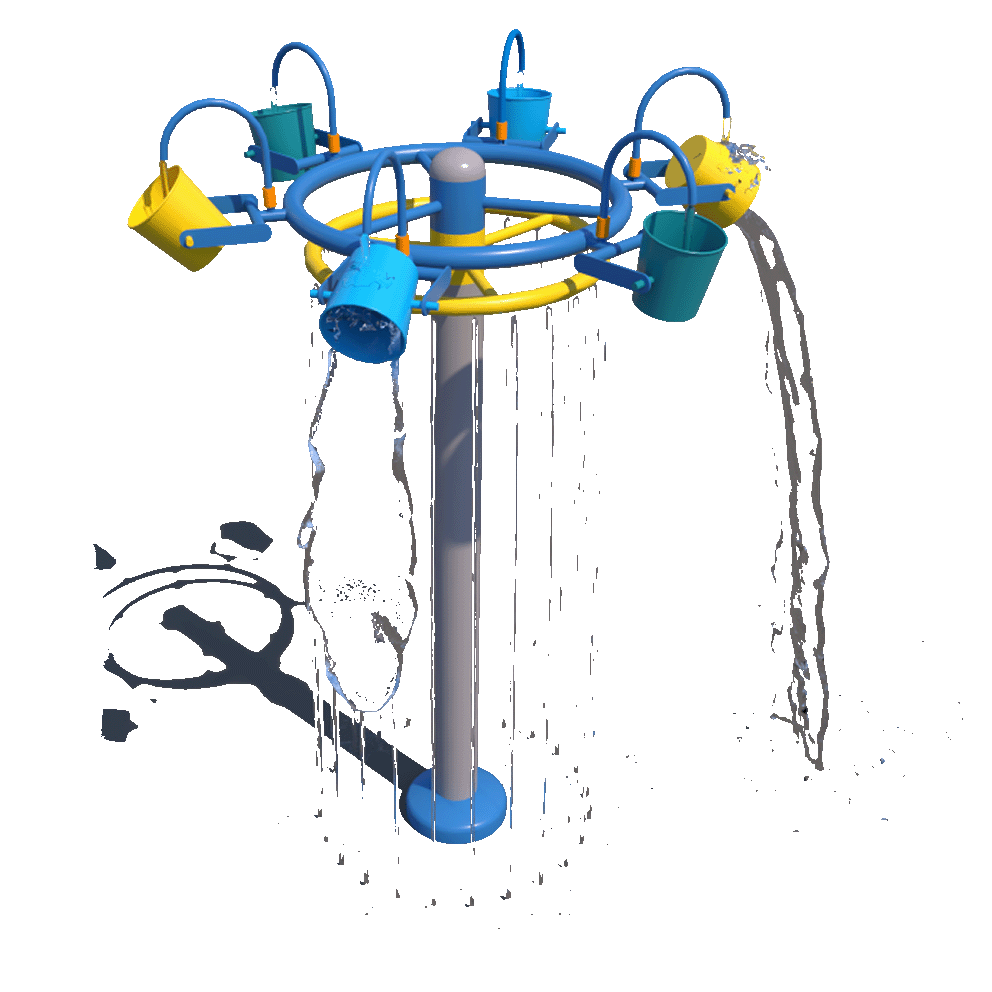

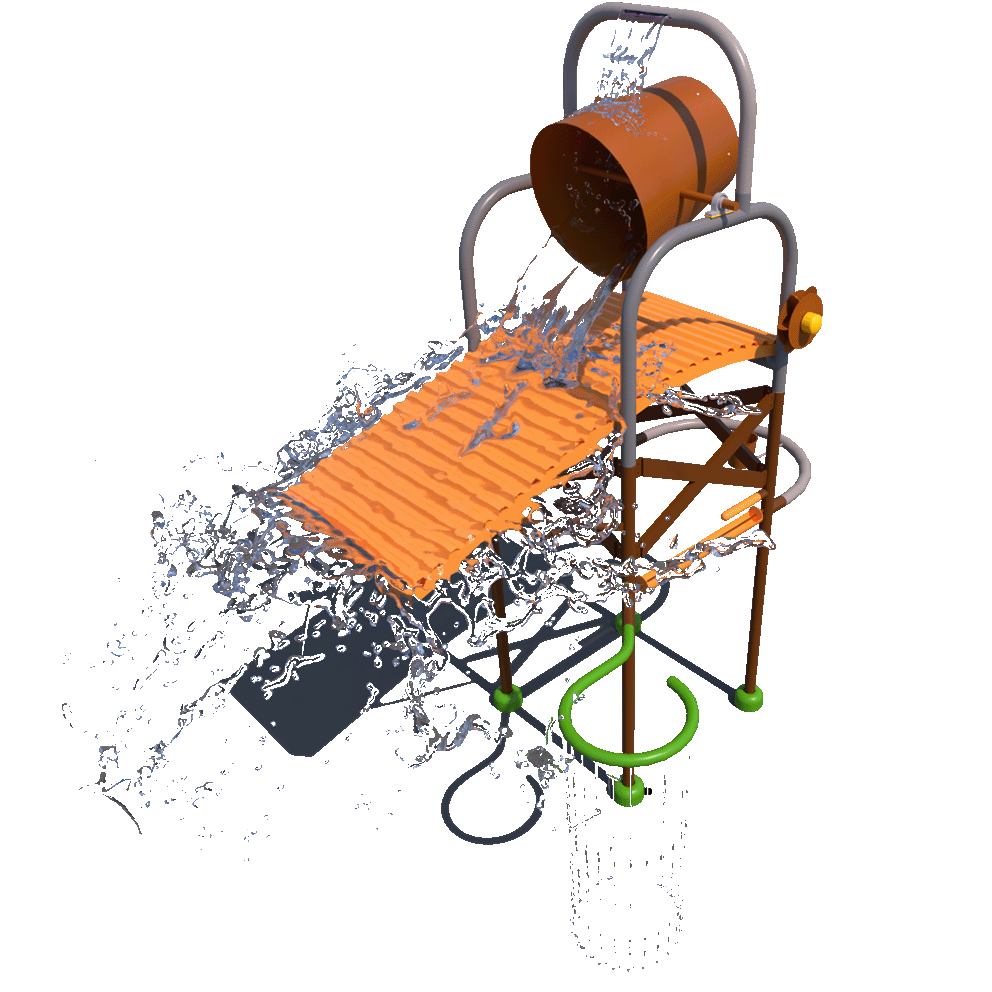

At Splashtacular, we take water attraction design from concept to reality. We build every slide, aquatic play unit, and spray feature with ingenuity, safety, and durability in mind.

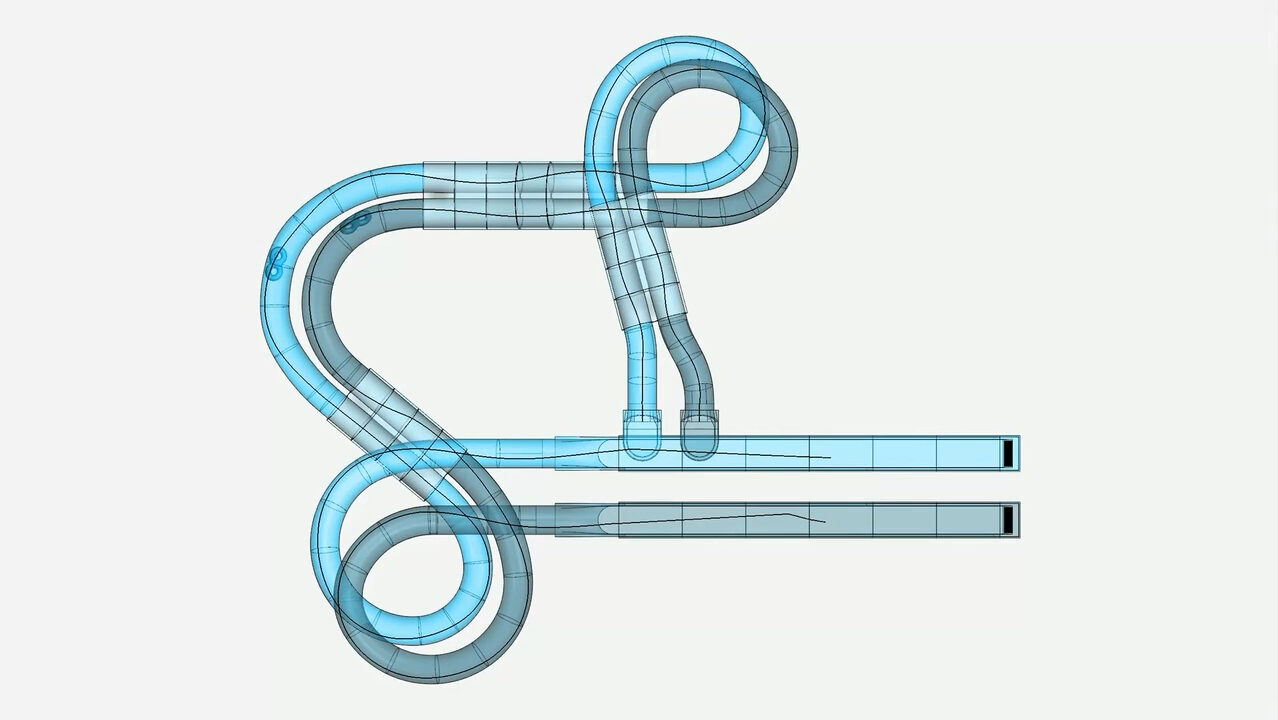

Once you reach out to our team, we’ll discuss more about the specifics of your project needs and goals. Our process starts with Splashworx, our proprietary design software, which brings your vision to life by visualizing the crucial design and engineering elements.

We conduct a ride path analysis using computer simulations to determine any points in the slide that may be unsafe for a rider. Then, we take it back to the drawing board to make adjustments, and repeat as needed until we can guarantee the product’s safety.

We build our water attractions using premium American-made steel from our warehouse near Kansas City. For a lightweight, corrosion-resistant alternative, we offer fiberglass-reinforced plastic (FRP) as a cost-effective option.

Our fiberglass production process includes cleaning, waxing, taping, and applying gel-coat, followed by fiberglass layering for strength. An optional insulation layer helps regulate temperature and reduce utility costs. Finally, our high-gloss protective coating keeps slides looking vibrant and new for years.

No matter the size or complexity of your project, Splashtacular is committed to creative solutions, high safety standards, and cutting-edge design. More than just a water slide supplier, we love building, testing, and riding our creations, and we’re confident you’ll love them just as much.